What are Positive Displacement Flowmeters?

A tried and true measurement technology for measurement of clean liquids, 'PD' or Positive Displacement flowmeters are a versatile and cost effective option for a wide range of applications. We'll explain how positive displacement flowmeters work, the different types of positive displacement flowmeter technologies, what the key benefits to using a positive displacement flowmeters are and where they are used.

How do Positive Displacement flow meters work?

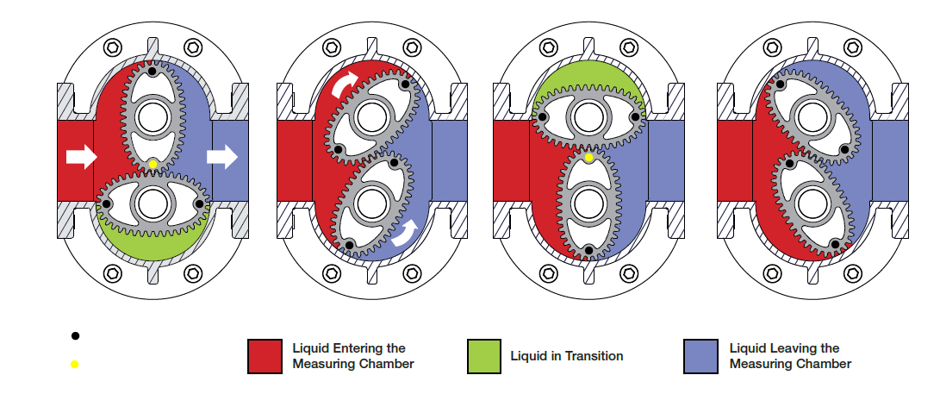

A 'PD' or positive displacement flow meter measures the fluid in discrete volumes. The fluid flows into a chamber, is sealed off once the chamber is full and produces either an electronic pulse or a drives a gear to register the volume as it exits the chamber. The meter in its simplest form would register each time a bucket is filled to the brim; the total volume would be the sum of the number of buckets filled. In a more complex meter the discrete volumes passed each time can be added to give the overall volume passing through the meter.

As illustrated in the example above, the pulse is generated as the liquid in green is sealed from both the inlet and exit. The pulse is typically generated by a magnet embedded in the rotor passing under a sensor that creates or switches a small voltage. The set up above would produce four pulses as the meter transmits four identical volumes for every cycle.

What are different types of Positive Displacement flow meter technologies?

Examples of meters using the positive displacement concept of measurement are oval gear meter, nutating disc meters, spur gear meters, variable area flow meters, screw meters, oscillating piston meters, helical gear meters, rotary vane meters. All the meters use very precise machining of a moving blade or gear against a uniform chamber wall.

What are the key benefits to using Positive Displacement flowmeters?

Positive displacement meters are a well-established technology but still hold advantages over more sophisticated metering methods such as;

- The ability to measure high and varying viscosities. Changes in temperature can create changes to the viscosity of a liquid being measured which can be a major cause of inaccuracy in other technologies, in particular inferential meters. Positive displacement meters measure discrete volumes with each pulse so are unaffected by these changes.

- Operation at very low flows with highly viscous liquids such as oils and greases without a loss of accuracy.

- No requirement for flow conditioning where inferential meters often require straight lengths of pipe either side to insure representative and reliable measurement.

- Its mechanical design offers versatility as it can be operated with a voltage pulse signal or it can simply be used with mechanical registers with no electrical power requirement; making it ideal for remote sites with low maintenance requirements.

- Positive Displacement meters are robust, able to operate with levels of noise and vibration and can operate without any maintenance with Last but not the least, it provides high accuracy and turndown ratio at an economic cost.

The positive displacement meters are best suited for viscous clean liquids that can lubricate the moving parts, typically fuels, oils and greases are the main application for them.

Where are Positive Displacement Flowmeters Used?

Positive displacement meters are widely used in various applications such as in inventory management of chemicals delivered ranging from detergents and deodorizers to low concentrated caustic and acid solutions. They are also being utilized to monitor fuel consumption for diesel generators for mining and construction sites. Small oval gear meters are used in fuel terminals for proportional blending of additives for fuels, such as anti-icing agents, combustion modifiers, corrosion inhibitors and antioxidants.

Although best suited for viscous fluid applications, they can also be utilized for metering fluids with low viscosity such as water, alcohol and organic solvents. Since these fluids typically have poor lubricity the meter may experience greater mechanical wear however rotors with self-lubricating plastics and ceramics can provide a suitable solution in these applications. The precision and high pulse resolution suits the meter to the dosing of small exact volumes. They can also be suitable for some food processing with edible oils, honey, molasses and chocolate all suited to be economically measured by positive displacement meters.

Positive Displacement flowmeters provide exceptional accuracy and repeatability in a wide range of applications measuring clean liquids.

Direct volumetric measurement from the positive displacement design gives you a flow measurement that is unaffected by changes in temperature, pressure, or viscosity – factors which can cause measurement errors in other flow meter technologies.

With a simple and reliable design concept using only two moving parts, they provide long service life and minimised maintenance costs.

For more information on Positive Displacement flowmeters you can contact us or fill out our form for assistance with specifying a flowmeter for your application.

Leave a comment